The Unsung Hero of Performance: Intercooler Technology

The roar of a turbocharged engine, the surge of power as you accelerate – these thrilling sensations are often attributed to the turbocharger itself. But behind the scenes, a critical component works tirelessly to maximize that performance: the intercooler. This often-overlooked piece of engineering genius plays a crucial role in boosting engine efficiency and power output, yet remains largely unsung in the world of automotive performance.

The Basics of Intercooler Technology

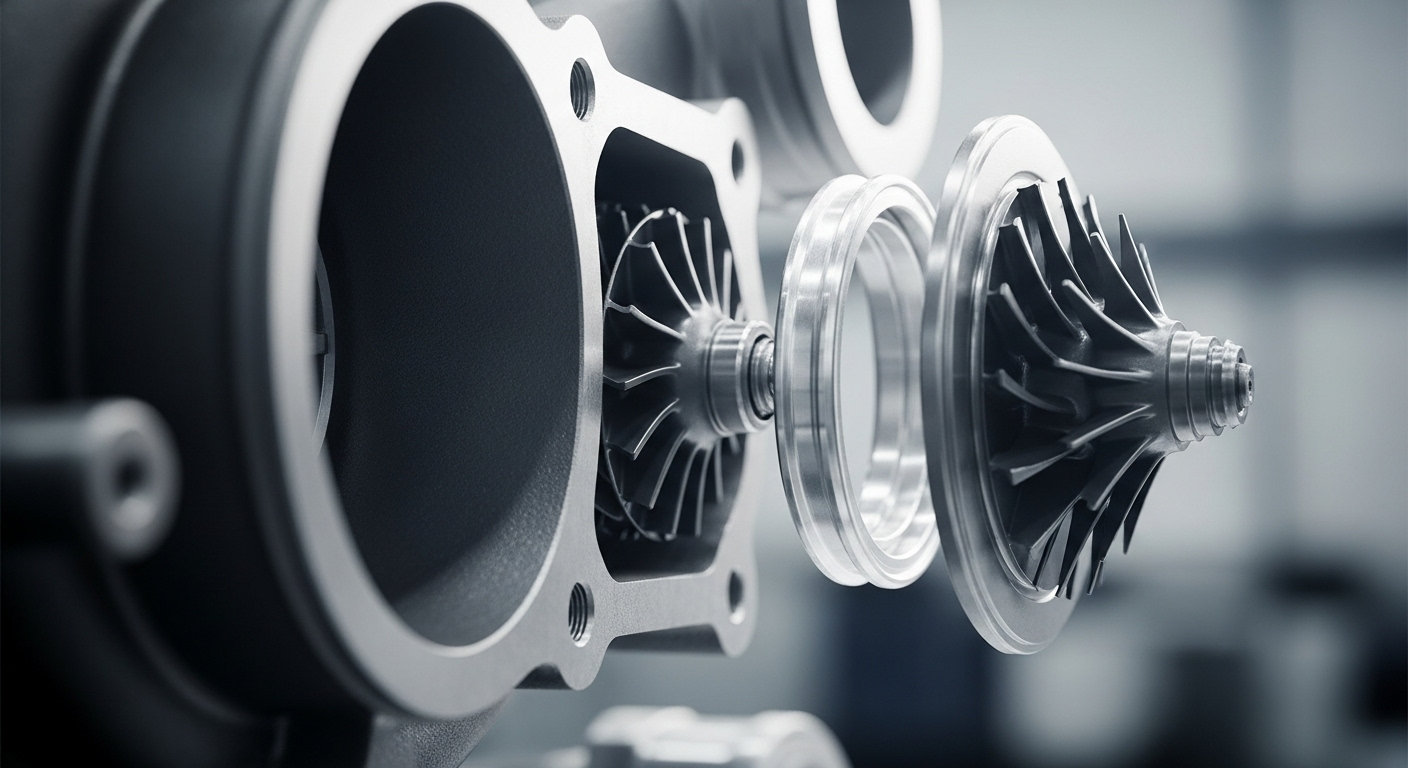

At its core, an intercooler is a heat exchanger designed to cool the compressed air coming from a turbocharger or supercharger before it enters the engine. When air is compressed, it heats up significantly – a phenomenon known as adiabatic heating. This hot, compressed air is less dense than cool air, which means fewer oxygen molecules per volume. Less oxygen means less efficient combustion and reduced power output.

Enter the intercooler. By cooling the compressed air, it increases its density, allowing more oxygen into the combustion chamber. This results in more efficient combustion, increased power output, and reduced risk of engine knock. It’s a simple concept with profound implications for engine performance.

The Evolution of Intercooler Design

Early intercoolers were relatively simple affairs, often consisting of a basic tube-and-fin design. As engine technology advanced, so did intercooler designs. Modern intercoolers come in various types, each with its own strengths and ideal applications.

Air-to-air intercoolers are the most common type found in production vehicles. They use the ambient air flowing through the intercooler to cool the compressed air. These are simple, reliable, and effective for most applications, but their performance can be limited in high-heat situations or when airflow is restricted.

Air-to-water intercoolers, on the other hand, use a liquid coolant to remove heat from the compressed air. This design allows for more consistent cooling performance, especially in high-demand situations. However, they are more complex and typically heavier than their air-to-air counterparts.

Materials Matter: The Role of Alloys in Intercooler Efficiency

The materials used in intercooler construction play a crucial role in their performance. Aluminum has long been the material of choice due to its excellent heat transfer properties and relatively light weight. However, recent advancements in metallurgy have led to the development of new alloys that push the boundaries of intercooler efficiency.

Some high-end manufacturers are experimenting with copper-infused aluminum alloys, which offer superior heat dissipation properties. Others are exploring the use of carbon fiber for intercooler end tanks, reducing weight while maintaining structural integrity under high pressure.

These material innovations are not just about performance – they also contribute to overall vehicle efficiency. Lighter, more effective intercoolers mean less parasitic loss on the engine, translating to better fuel economy without sacrificing power.

Beyond Cooling: The Aerodynamic Challenges of Intercooler Placement

Designing an effective intercooler system isn’t just about the cooler itself – it’s also about where and how it’s integrated into the vehicle. Placement is crucial for maximizing airflow and minimizing the distance the compressed air must travel.

Front-mounted intercoolers are common in many performance vehicles, taking advantage of direct airflow. However, this placement can present challenges in terms of aerodynamics and front-end packaging. Some manufacturers have experimented with top-mounted intercoolers, particularly in vehicles with hood scoops, to balance cooling efficiency with aerodynamic considerations.

More recently, some high-performance vehicles have adopted dual intercooler setups, with one cooler on each side of the engine bay. This configuration allows for shorter air paths and more even cooling across both banks of a V-configuration engine.

The Future of Intercooling: Smart Systems and Integration

As vehicles become more technologically advanced, so too do their cooling systems. The future of intercooler technology lies in smart, integrated systems that can adapt to changing conditions in real-time.

Variable geometry intercoolers, which can adjust their internal flow characteristics based on engine load and ambient conditions, are on the horizon. These systems promise to deliver optimal cooling across a wider range of operating conditions, further enhancing engine efficiency and performance.

Additionally, we’re seeing increased integration of intercooler systems with other vehicle subsystems. For example, some manufacturers are exploring ways to use waste heat from the intercooler to warm the cabin in cold weather, improving overall vehicle efficiency.

The humble intercooler, once a simple heat exchanger, is evolving into a sophisticated component that plays a critical role in the overall performance and efficiency of modern engines. As we continue to push the boundaries of automotive technology, the importance of effective intercooling will only grow. From everyday commuters to high-performance sports cars, the intercooler remains an unsung hero, quietly enabling the thrilling performance we’ve come to expect from modern vehicles.